The high temperature materials laboratory operates out of the Science and Engineering Research Facility (SERF) building on the campus of the University of Tennessee Knoxville (UTK). It is currently developing, investigating and prototyping ceramics for space nuclear applications, with a particular focus on synthesis, characterization and testing. Fundamental research programs have been successfully conducted on refractory metals for high temperature heat exchange applications. This has led to research output that has improved understanding of the processing and properties crucial in materials selection for sponsors in the aerospace industry.

Industry and proprietary research programs are also conducted at the facility. These are sponsored at a variety of Technology Readiness Levels (TRLs) from 2-6. In particular, assignments to fabricate and develop near-prototypical morphology under industry/UTRF agreements are a common workscope of this facility.

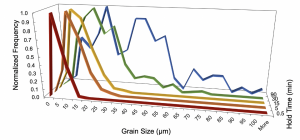

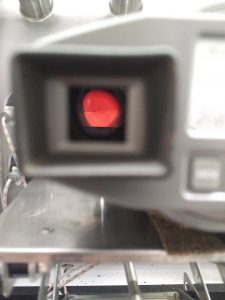

A variety of analytical approaches are used to ensure consistent synthesis and quality control. Metrology is a significant endeavor for a laboratory involved in both fundamental and applied research. Instrumentation includes radiation feedback and thermocouples for temperature, standard solutions for liquids, gas pressure methods for vapors, gas and moisture sensor systems, and their supporting traceable NIST materials and calibration articles are present in the facility. Reference fabrications using distinct but complementary approaches are often used in order to rule out impurities or differences in partial pressure. This systematic approach recognizes the broad complexities of materials development, and the recognition that a change in a single detail has consequences on development downstream and upstream.

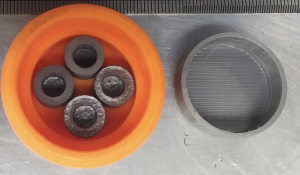

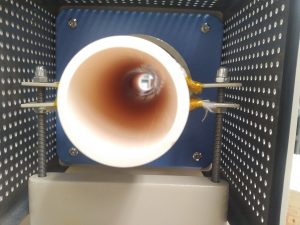

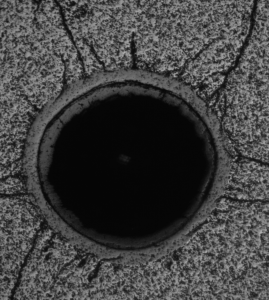

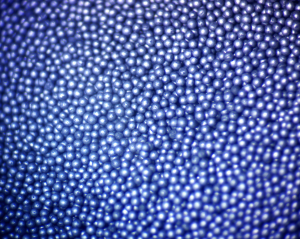

The facility also has a significant history and technical expertise in the process, control and development of particle fuels. In particular, the refinement of particle fuels encapsulated in a ceramic or graphite matrix was the original purpose of the laboratory. Such particles include non-conventional surrogate kernels based on UC and UC2, as well as the traditional UO2 and UCO. Several variations of coatings have been experimented and tested in the facility with ceramics, include CVD pyrolytic carbon (OPyC, IPyC, buffer) as well as CVD ZrC and SiC.

Several graduate students at both Masters and PhD level conduct research under both industry and federally sponsored programs. There are also several undergraduates from both the Department of Nuclear Engineering and the Department of Materials Science and Engineering either conducting their own research projects for the Center for Materials Processing (CMP) or enabling other programs. A significant inventory, quality control, equipment training and safety program is overseen by the presence of both industry and university PIs. In addition, collaboration continues between research, facilities and administrative staff, recognizing their vital role in improving and maintaining infrastructure and capability.